Power fuses and Industrial fuses manufacturer and distributor

Discover our selection of industrial fuses and power fuses

Power fuses and industrial fuses: all you need to know

Power fuses and industrial fuses are essential for protecting electrical systems from overcurrent conditions that can lead to equipment damage and fire hazards. Industrial power fuses are specifically designed for high-voltage applications, safeguarding transformers and motors. These fuses also feature high interrupting ratings, ensuring they can safely protect circuits from the very high currents that can occur during a short circuit in an industrial setting.

OptiFuse UL listed industrial fuses maximize current protection in a low-profile design. When selecting a circuit protector, it's crucial to differentiate between branch circuit protection and supplementary protection: Class CC, Class T, Class J, and Class RK5 fuses provide overcurrent and short-circuit protection for power and lighting feeders as well as branch circuits, while OptiFuse Midget fuses are ideal for supplemental protection. Understanding these differences and their applications is vital for choosing the right fuse to ensure operational reliability in electrical systems.

Current ratings of industrial fuses

Depending on the model, the ratings of each style of fuse may vary.

Class RK5 fuses provide voltage ratings up to 250VAC and 150VDC. Their amperage ratings reach up to 60A, while the interrupting capacity reaches up to 200kA AC and 50kA DC.

Class J fuses provide voltage ratings up to 600VAC and 500VDC. Their amperage ratings reach up to 600A, while the interrupting capacity reaches up to 200kA AC and 100kA DC.

Class T fuses provide voltage ratings up to 600VAC and 300VDC. Their amperage ratings reach up to 1200A, while the interrupting capacity reaches up to 200kA AC and 50kA DC.

Class CC fuses offer voltage ratings up to 600VAC and 300VDC. Their amperage ratings reach up to 30A, while the interrupting capacity reaches up to 200kA AC and 20kA DC.

Midget fuses offer voltage ratings up to 600VAC and 600VDC. Their amperage ratings reach up to 30A, while the interrupting capacity reaches up to 100kA AC and 10kA DC.

For more detailed specifications and ratings of each OptiFuse industrial fuse, please refer to the OptiFuse website and navigate to the appropriate product section.

Common applications of industrial fuses

Common applications for Class RK5 fuses include:

- Branch Circuit Protection | Motor Overload Protection | Industrial Equipment | Air Conditioning Units | Pumps

Common applications for Class J fuses include:

- Branch Circuit Protection | Motor Circuits | Feeders | Lighting | Heating | Transformers | Control Panels | Load Centers

Common applications for Class T fuses include:

- Branch Circuit Protection | Lithium-Ion Battery Protection | Inverter Protection | Variable Frequency Drives (VFDs) - These are often found in pumps, compressors, and HVAC industries | Meter Stacks

Common applications for Class CC fuses include:

- Branch Circuit Protection | White goods | Street Lighting | VFDs | Transformers

Common applications for Midget fuses include:

- Supplementary Circuit Protection | VFDs | Lighting | Transformers

Classes of UL fuses

Fuses are categorized into various classes based on their design, application, and specific characteristics. Here are the main classes of fuses that OptiFuse offers:

Class CC

These fuses are suitable for branch circuit protection and offer current-limiting capabilities. They have a voltage rating of up to 600VAC and 300VDC, with amperage ratings reaching up to 30A.

Class T

Class T fuses provide high current-limiting protection for power and lighting feeders and branch circuits. They can have voltage ratings up to 600VAC and 300VDC, with ratings up to 1200A.

Class J

Class J fuses are designed for branch circuit protection and offer excellent current-limiting capabilities. They have voltage ratings up to 600VAC and 500VDC, with amperage ratings ranging from 1A to 600A. Available in fast-acting and time-delay styles.

Class RK5

Class RK5 fuses are robust time-delay fuses rated for branch circuit protection, particularly motor overload protection. They have voltage ratings up to 250VAC and 150VDC, with amperage ratings reaching up to 60A.

Midget Fuses

Midget fuses offer a compact design with voltage ratings up to 600VAC and 600VDC. They are commonly used in various applications, including motor protection.

Understanding the different classes of fuses is essential for selecting the appropriate fuse for specific applications to ensure safety and reliability in electrical systems. For more details, you can also review our industrial power fuses brochure.

FAQs

What regulations or standards must industrial fuses comply with?

Industrial fuses must comply with several key regulations and standards to ensure safety and performance. All industrial fuses are required to be UL listed, confirming they meet the safety and performance criteria established by Underwriters Laboratories. Specific UL standards apply to different fuse classes, such as Class J (UL 248-8), Class RK5 (UL 248-12), Class T (UL 248-15), Class CC (UL 248-4), and Midget fuses (UL 248-14), outlining requirements for construction, performance, and testing to ensure reliable operation.

Additionally, fuses that offer current limiting capabilities, such as Class CC and Class T fuses, must be labeled as "Current Limiting" to indicate their enhanced protection against overloads and short circuits.

What are UL standards used for?

UL standards are used to establish safety, performance, and reliability benchmarks for a wide range of products, particularly electrical and electronic devices. They ensure that products meet specific safety requirements to minimize risks of fire, electric shock, and other hazards by providing guidelines for safe design and construction practices. UL standards also define testing protocols to evaluate product performance under various conditions, ensuring effectiveness in preventing electrical faults and overcurrents.

Compliance with these standards is often required by regulatory frameworks, and UL listing provides market confidence, allowing consumers to make informed decisions about product safety.

When is UL certification required?

UL certification is essential for ensuring safety and compliance with industry standards, often required by local, national, and international electrical codes. Certain markets, particularly in North America, require UL certification for entry, especially in high-risk industries like healthcare and construction.

While UL certification may not always be necessary for every project, using components with the UL marking instills confidence in customers regarding product reliability.

What is the function of a current limiting fuse?

Current limiting fuses function as their name implies: they limit the amount of current that can flow through a circuit during a short circuit event. This crucial limiting factor allows for selective coordination within the circuit, enabling downstream protective devices to effectively interrupt a current that remains within their interrupting capacity.

One of the key benefits of using current limiting fuses is that, in the event of a fault, only the affected section loses power rather than requiring a complete shutdown of the entire line. This targeted protection enhances system reliability and minimizes disruptions to operations, making current limiting fuses an essential component in electrical systems where safety and efficiency are priorities.

Can I replace a fast acting fuse with a time delay fuse?

Time-delay fuses should not be used as a replacement for fast-acting fuses. Time-delay fuses are specifically designed to allow temporary surges of current to pass through to downstream devices before tripping, helping to prevent nuisance tripping in circuits where inrush current is expected.

Using a time-delay fuse instead of a fast-acting fuse may expose surge-sensitive downstream components to dangerous overcurrents that those components are not built to withstand, potentially leading to damage or failure. Always ensure that the correct fuse type is selected for optimal protection and performance.

See Also

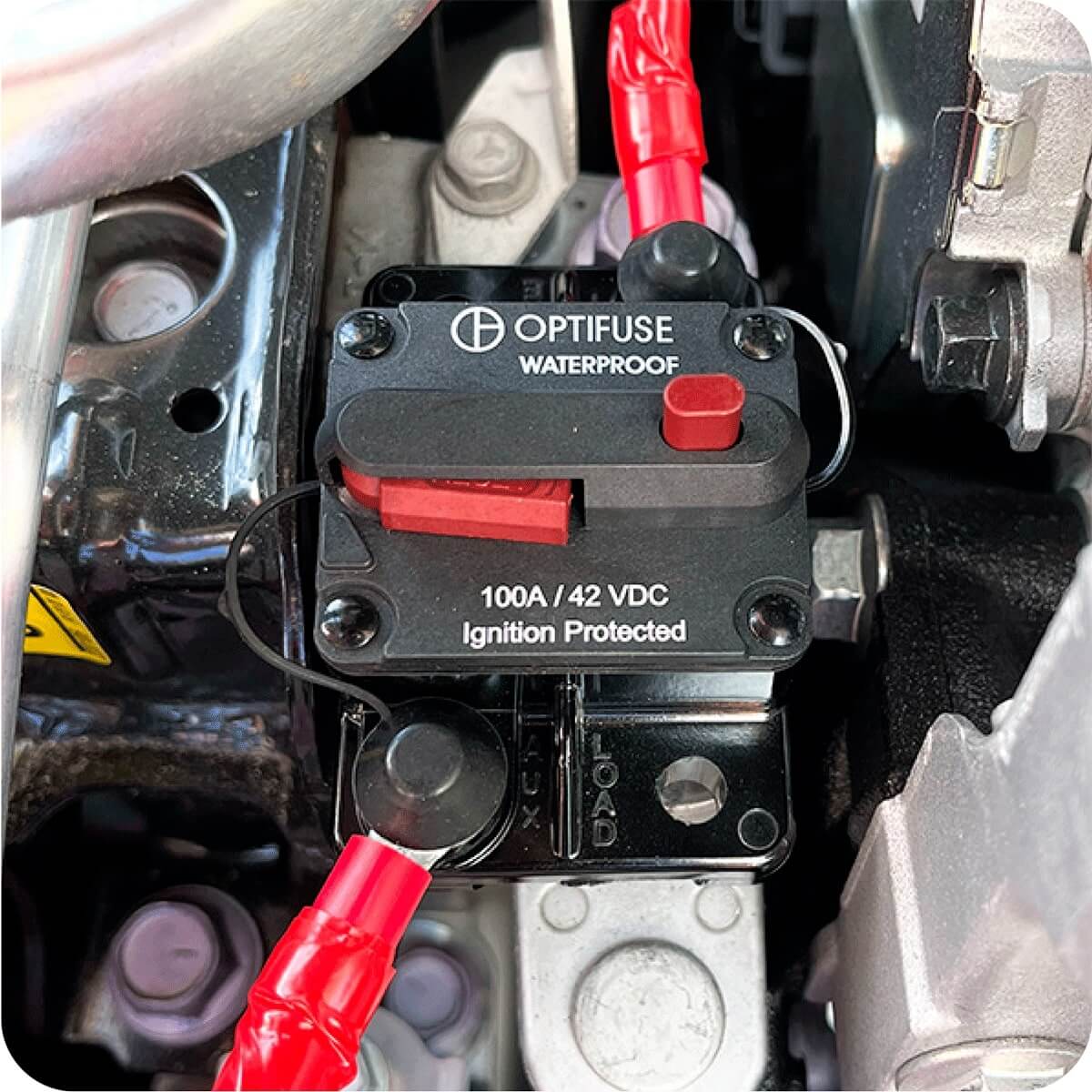

Circuit Breakers

A comprehensive range of automotive, marine grade and line voltage circuit breakers to protect applications where resettability is needed.

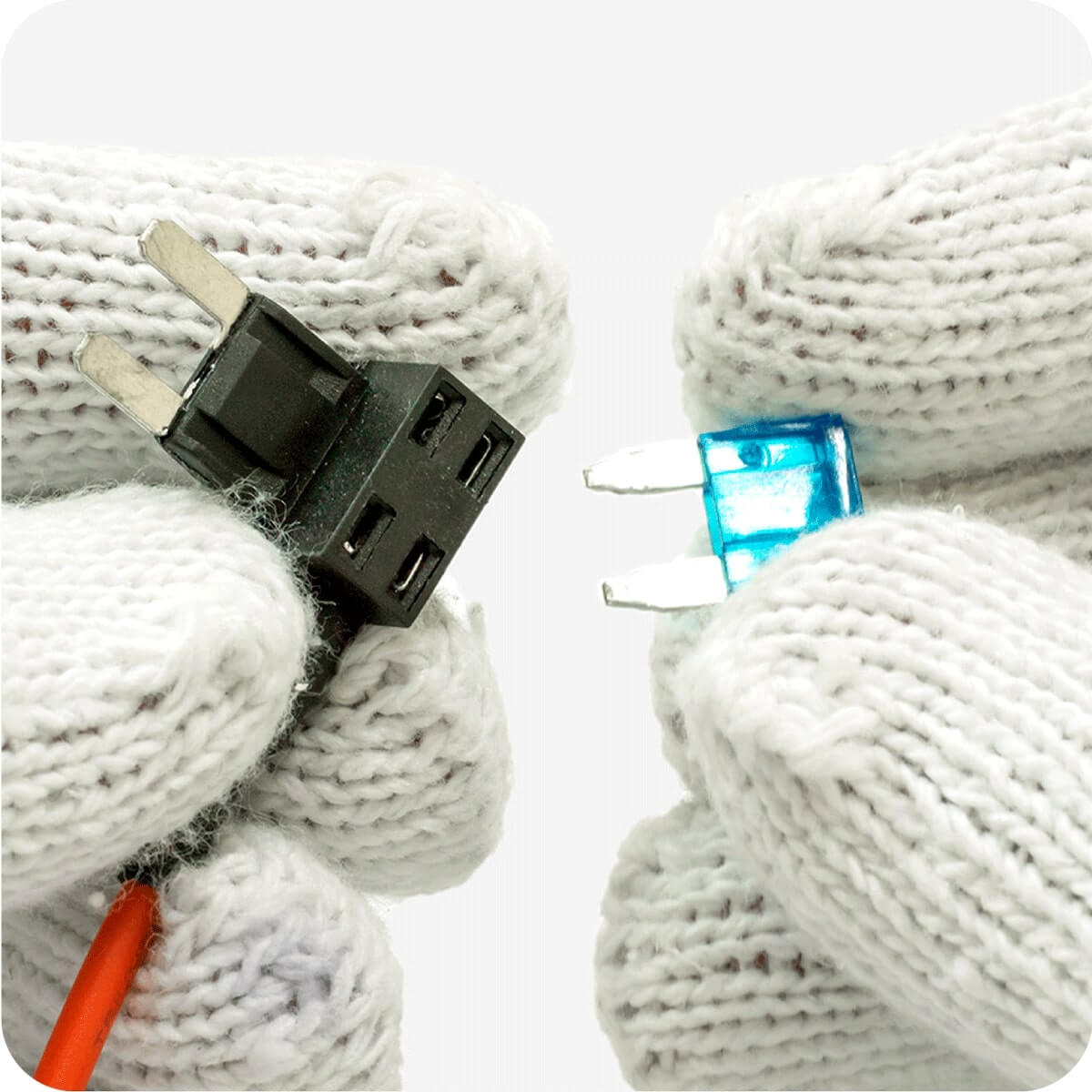

Fuse Holders, Blocks and Accessories

Installing circuit protection is easy with our wide variety of customizable fuse holders, sturdy fuse blocks, and compact fuse clips.