Automotive blade fuse holders and blocks manufacturer and distributor

Discover our selection of fuse holders and blocks for automotive blade fuses

Additional components to integrate fuses into electrical systems

Fuse Holders for automotive blade fuses

Fuse Holders for automotive blade fuses securely mount automotive blade fuses, ensuring reliable connections and easy replacement. They are compatible with various fuse sizes and often feature weatherproofing and straightforward wiring terminals.

Blocks for automotive blade fuses

Blocks for automotive blade fuses organize multiple fuses in one location for compact wiring solutions, offering multiple fuse slots, built-in indicators for fuse status, and easy mounting options.

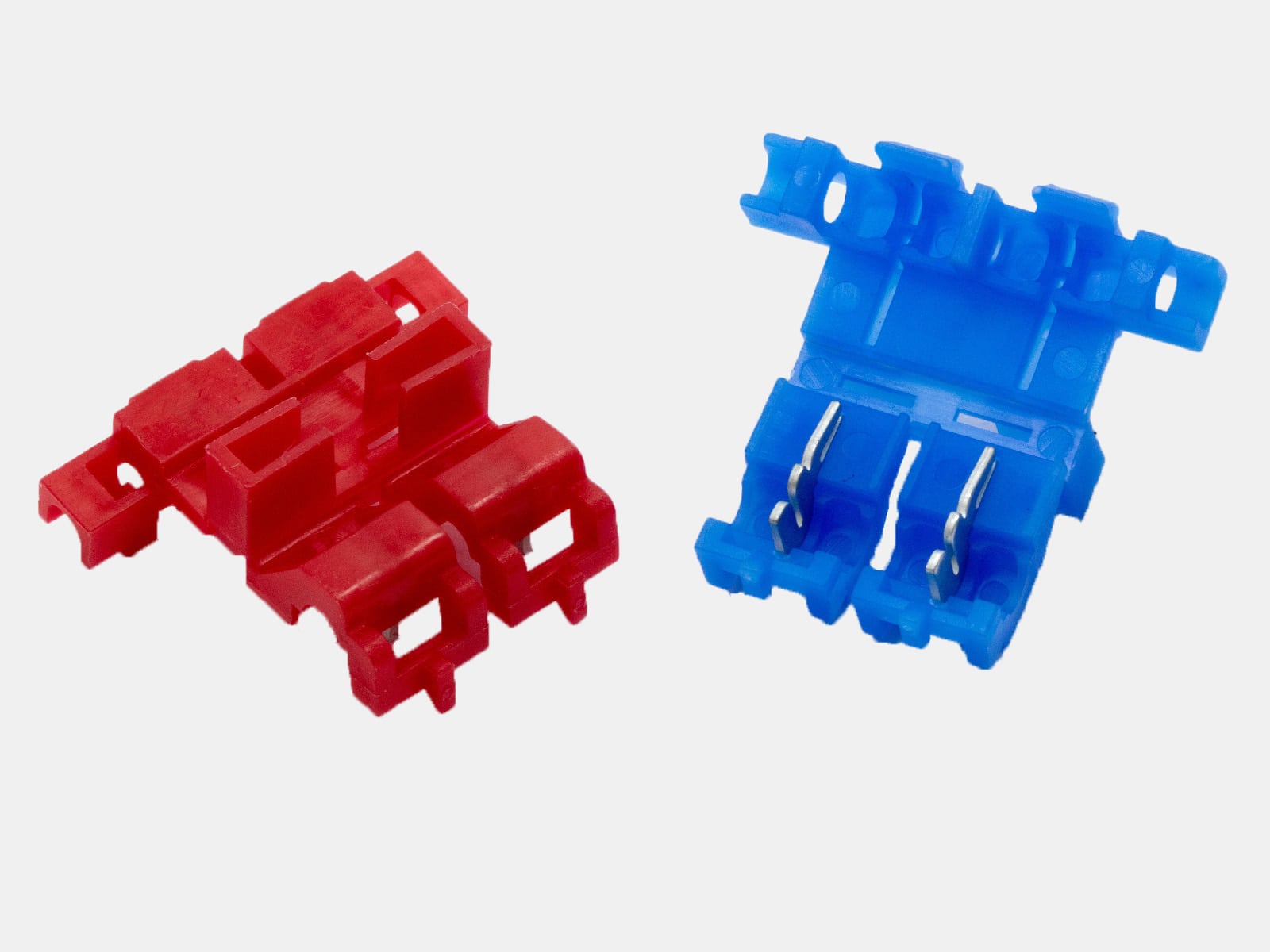

Accessories for automotive blade fuses

Other Accessories for automotive blade fuses include fuse pullers, which allow for the safe removal and replacement of fuses.

To browse the complete line of OptiFuse mounting solutions for blade fuses, visit the OptiFuse website and use the top row to select "Automotive Blade Fuses" under "Fuse Holders, Blocks, and Accessories". Then, select the type of mounting solution you would like and browse the relevant products.

FAQs

How to install the fuse holders?

To install fuse holders, the method depends on the style of the holder. For in-line fuse holders, connect the wires coming off the fuse holder directly to the wires in your application using crimping or soldering as the connection method. For IDC (Self-Stripping) fuse holders, remove or re-splice the holder by inserting the wire on each side and then folding the splicing arm over for a self-stripping and self-tapping connection.

How do I choose the right fuse holder for my application?

- Fuse Size: Determine the size of the fuse you will be using (e.g., mini or maxi blade fuses) and ensure that the fuse holder is compatible with these specifications.

- Electrical Rating: Check the current and voltage ratings of the fuse holder, which should match or exceed the ratings of the circuit to ensure safe operation.

- Mounting Style: Decide on the appropriate mounting style for your application based on your design and space constraints.

- Environmental Conditions: Consider the operating environment. If the fuse holder will be exposed to moisture, dirt, or extreme temperatures, look for weatherproof designs (e.g., IP-rated enclosures).

- Indicator Features: Look for fuse holders that offer built-in indicators for blown fuses, which can simplify troubleshooting and maintenance.

- Compliance and Standards: Ensure the fuse holder complies with relevant industry standards and certifications for safety and performance.

How to install the fuse blocks?

Fuse blocks are typically offered in a surface mount style and can be directly bolted down to your application. To install, start by selecting a suitable location and securing the fuse block using screws or bolts. The input power should connect to the positive side stud, typically found on the bottom or top of the block, while the output power is connected at each connection point for each individual blade fuse. This output power is usually connected via quick connect tabs or screw terminals, ensuring a secure and reliable installation.

How do I choose the right fuse block for my application?

- Fuse Size: Determine the type and size of fuses you will use and ensure the fuse block is compatible with these specifications.

- Current and Voltage Ratings: Check the current and voltage ratings of the fuse block to ensure they meet or exceed the requirements of your circuit, ensuring safe operation.

- Number of Circuits: Consider how many circuits you need to protect and select a fuse block that accommodates the required number of fuses.

- Available Mounting Space: Assess the available space in your application to ensure the fuse block can be securely mounted without interfering with other components.

- Connection Method: Evaluate the connection method used by the fuse block, such as screw terminals or quick connect tabs, ensuring it aligns with your installation capabilities and preferences.

- Environmental Considerations: Assess the environmental conditions where the fuse block will be installed. If it will be exposed to moisture, dust, or extreme temperatures, opt for designs with an insulating cover.

- Indicator Features: Look for fuse blocks that offer built-in indicators for blown fuses, which can simplify troubleshooting and maintenance.

- Required Grounding Block: Determine if a grounding bar is necessary for your application to ensure proper electrical safety.

- Compliance and Standards: Ensure the fuse block meets relevant industry standards and certifications for safety and performance.

What accessories do I need for blade fuse installation/removal?

For fuse installation and removal, fuse pullers are essential accessories that provide safety and ease of use. Designed specifically for handling fuses, they allow users to securely grip and remove fuses without risking damage to the fuse or holder, reducing the likelihood of electrical shock.

What is the lifespan and durability of the fuse holders and blocks?

Fuse holders and blocks do not have a set shelf life and should function effectively as long as there are no external issues, depending on factors such as material quality, environmental conditions, and electrical load. Regular maintenance and inspections can help ensure that both fuse holders and blocks remain safe and functional.

It should be noted that the fuses are one-time use only and must be replaced once they have opened.

If corrosion is observed on either the fuse or the fuse holder, it is recommended to replace the part to ensure that the electrical characteristics remain unchanged.

See also

Fuses

Many styles of innovative, versatile fuses are available to protect circuits from dangerous overcurrents in automotive, electronic, and industrial applications.

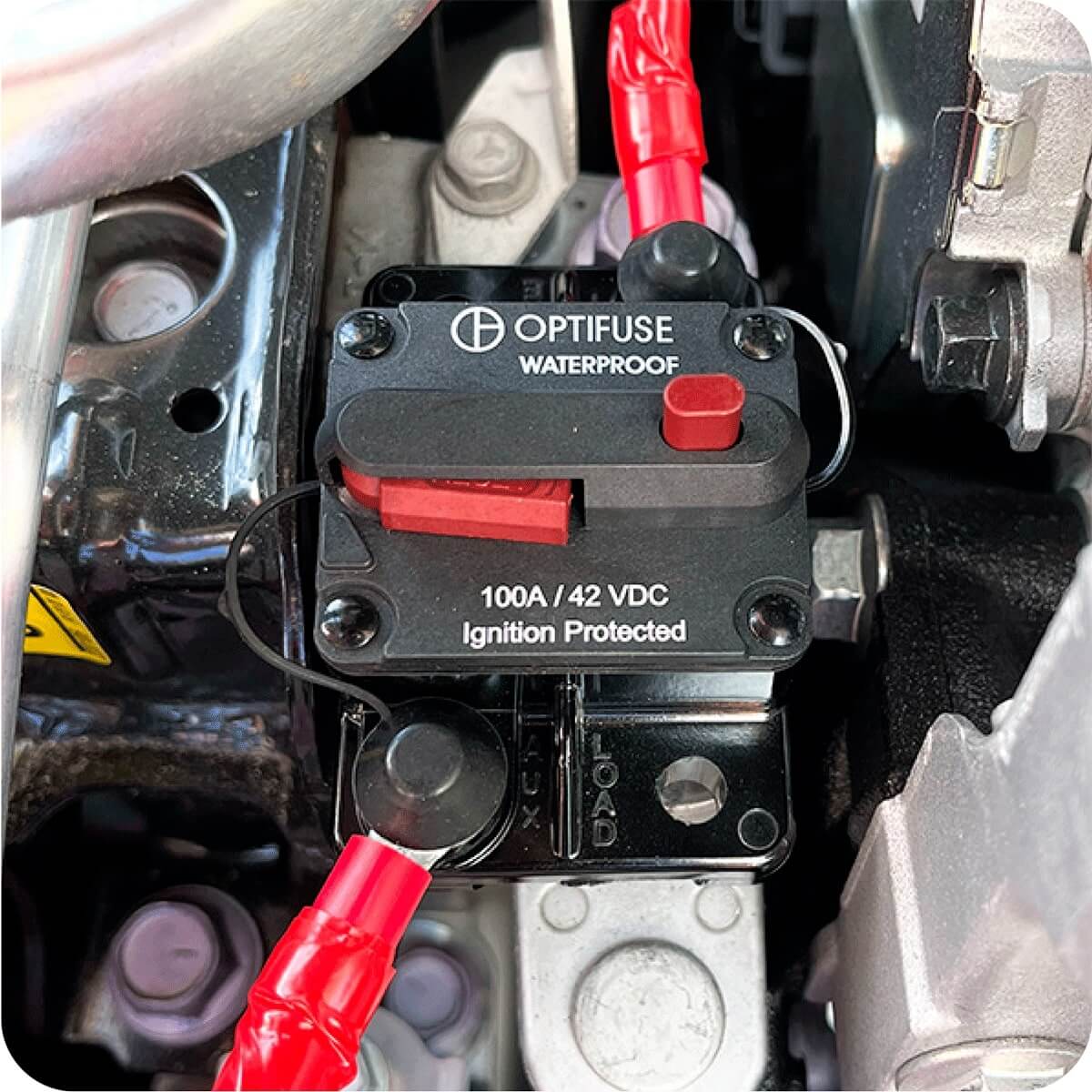

Circuit Breakers

A comprehensive range of automotive, marine grade and line voltage circuit breakers to protect applications where resettability is needed.