Circuit Protection Types: Fuses vs. Circuit Breakers

Choosing the right circuit protection devices for your applications is crucial for protecting your employees, your equipment, and of course yourself. Of the devices available to choose from, there are two predominant categories: fuses and circuit breakers.

Both devices serve the same purpose, to protect electrical circuits against damaging and dangerous overcurrents. But they do so in different ways. Fuses have a filament inside that melts when overheated, cutting off the current flow. Circuit breakers, meanwhile, have switch mechanisms that trip at the onset of unsafe surges of electricity. More technically, they have a bi-metal strip that bends and opens the circuit, cutting off current flow. This bi-metal strip can unbend and resituate itself back on the contact post, re-connecting the circuit. This unbending capability is what provides resettability to circuit breakers. Those and other key differences between fuses and circuit breakers should be considered before deciding which device best meets your needs.

Fuses

Designed to allow electric currents to safely flow during normal operation but will quickly open when an overcurrent develops. Their defining characteristics include their physical size, interrupting ratings, construction, opening speed, electrical ratings and safety agency approvals.

Fuses generally react quicker to overcurrents than circuit breakers and are usually cheaper, but they must be replaced after they have been used to deter one overcurrent. There are resettable fuses (PTCs) available for certain applications, but unlike circuit breakers, most fuses must be replaced after a single use.

In general, fuses are more widely available than circuit breakers and they offer a smaller footprint.

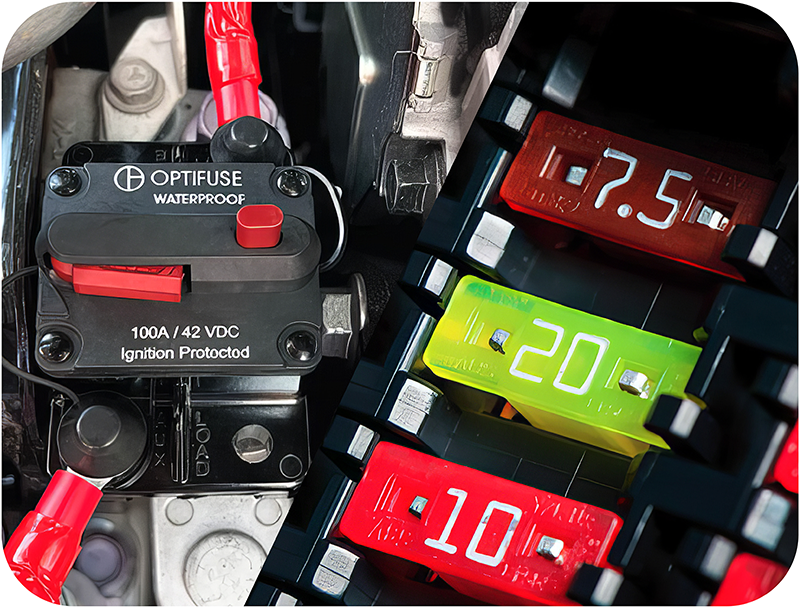

Circuit Breakers

Circuit Breakers differ from fuses because they can be repeatedly tripped and reset in the event of overcurrents. They do not need to be replaced after each use like most fuses do.

Circuit Breakers, come in one of three different reset types. Depending on which type you choose, the breaker will either reset itself automatically or will require you to manually reset it to restart the flow of electricity following an overcurrent event.

Devices work well in relatively low voltage applications and are great for applications in which overload situations are rare and for which the circuit breaker must be installed in a hard-to-reach space in the vehicle.

Circuit breakers are best for applications that only need circuit protection when the vehicle’s engine is turned on, because these breakers will reset when the engine is turned off.

Breakers generally offer higher current protection and work well to draw attention to underlying problems in a circuit, because any equipment the breaker protects won’t start up again until the breaker is reset by hand.

Compared to fuses, circuit breakers are typically more expensive but are also more robust and can protect against higher currents and amperages. That is especially true of our heavy duty high amperage circuit breakers. They are built to handle the heavy duty loads associated with many vehicles. Some of our circuit breakers also come with external status indication that helps users determine when the device is tripped and, in the case of Type III breakers, when it needs to be reset.

Key Differences

Fuses are a low-cost overcurrent protection option for applications that typically don’t have high electricity needs. In exchange for their low cost comes a mild inconvenience, they must be replaced after one use. Fuses typically have a smaller footprint and come in a larger variety of styles and sizes.

Circuit breakers, on the other hand, are generally more robust than fuses and have the advantage of not needing replacement every time they trip. Despite the higher cost, circuit breakers can be more economical over time, especially in environments where frequent tripping occurs, since they only need to be reset, whereas fuses would need to be replaced after each fault.