How to Choose a Tube Fuse

Tube fuses have long been a standard circuit protection device. Built out of different materials and coming in different sizes, they are dynamic circuit protectors with many uses across multiple industries.

Same as for the other fuses, in order to select the proper tube fuse three electrical ratings need to be considered: nominal current, voltage, and interrupting rating. Additionally, in applications in which the fuse must sustain large current pulses of a short duration, the nominal melting I2t should be analyzed too. See our Fuse Selection Guide for complete context.

Besides these general considerations, there are other parameters specific for tube fuses that are involved with the fuse selection. They come in various sizes, glass or ceramic constructions, distinct response time, and are built for use for use in a myriad of industries. Below, we provide help for how to choose the best tube fuse for your applications.

Fuse Size and Use: Consumer Electronics

Glass and ceramic tube fuses conveniently protect appliances and consumer electronics. Many of these appliances lack space for larger, costlier circuit protection devices and fuses become the preferred method of protection due to their accuracy, small size, and reliability.

These fuses are widely used throughout the world beyond North America, so they are commonly identified in mm instead of inches.

Glass and Ceramic tube fuses designed for electronic/electrical applications are rated at 125 V or better. Four sizes of user-replaceable fuses are found: 3.6 x 10 mm, 5 x 15 mm, 5 x 20 mm, 6.3 x 32 mm.

There are a few side notes to the above:

• 5 x 15 mm easily replaces the 2AG size fuse.

• 6.3 x 32 mm fuses are equivalent to 3AG (1/4” x 1 1/4”).

Fuse Size and Use: Automotive

Used in older-model North American cars, glass tube fuses today are found primarily in automotive accessory applications (12V).

In the early days of fuses and automobiles manufacturers created their own individualized parts to fulfill different needs as they arose. Over the years, standardization of parts began to take root and new systems were adopted for sizing fuses.

AG Fuses

The “AG system” of sizing fuses, (where “AG” stands for “Automotive Glass”) vary in length, diameter and amperage rating. Below you will find a table of dimensions cross referencing the common AG size to the corresponding dimensions:

SFE Fuses

Engineered to specifications set by the Society of Fuse Engineers, the “SFE system” sized fuses (OptiFuse’s FSO Series) are always 1/4″ in diameter, but their length depends on the current rating, ranging from 5/8″ for a 4A, to 1-7/16″ for a 30A, to ensure accurate fuse replacement.

4A

5/8 (0.625)

1/4 (0.250)

6A

3/4 (0.750)

1/4 (0.250)

7.5A

7/8 (0.875)

1/4 (0.250)

9A

7/8 (0.875)

1/4 (0.250)

14A

1 1/16 (1.0625)

1/4 (0.250)

20A

1 1/4 (1.250)

1/4 (0.250)

30A

1 7/16 (1.4375)

1/4 (0.250)

Fuse Response Time

When talking about fuse response time, it is good to know about overcurrents. There are generally two types of overcurrents – short circuits and overloads. Short circuits consist of very high currents that can cause harm to both people and equipment. Overloads typically occur when too many devices are added to a circuit and the normal rating of the circuit is exceeded.

There are times when temporary overloads cannot be avoided. For example, when a circuit is first energized or when a motor starts up. These overload conditions generally last between 1 and 5 seconds, with the overload subsiding once the motor has reached its operating speed or the circuit has been fully energized.

These temporary overloads are sometimes called transient currents and are normally 2 to 6 times the normal current of the circuit. They are completely normal but can cause problems if the overcurrent protection device isn’t properly selected.

In come fuse response times. In circuits where transient currents exist, a time-delay fuse should be used (sometimes a time delay fuse is also called a time lag or slow-acting fuse. A time delay fuse allows the overload to exist for a few extra seconds before opening and thus avoiding a nuisance opening from the transient current condition. OptiFuse series such as TCA, TSA and TSD provide time-delay characteristics suitable for these applications.

The terms “time delay” and “fast-acting” are for overloads and/or transient currents only. Both time delay and fast-acting fuses are very quick acting when it comes to opening short circuits.

If fast acting fuses aren’t fast enough, there are also super-fast acting fuses like the OptiFuse SCA series. These super-fast acting fuses are primarily used for protecting sensitive equipment, such as rectifiers, SCRs, and transistors. Because these fuses are so high performing, they can cost as much as ten times normal fast-acting fuses.

UL vs. IEC Fuses

The reason for this is that FSC fuses are designed to meet UL standards and FSD fuses are designed to meet the European IEC standards. The differences are in the response times of these fuses.

Note that it is impossible to be open (UL standard at 135%) and be closed (IEC standard at 150%) at the same time.

Because of these two different standards, fuse manufacturers are required to design and construct two different fuses depending on whether the equipment will be used in Europe or in North America.

UL standards dictate that a fast-acting fuse must operate under the following conditions (UL standard 248-14):

The corresponding IEC standards dictate that a fast-acting fuse must operate under the following conditions:

Fuse’s Rated Current Openning Time

Fuse’s Rated Current Openning Time

110% the fuse must stay closed for a minimum of 4 hours.

135% the fuse must open within 1 hour.

200% the fuse must open within 5 seconds.

150% the fuse must remain closed for 1 hour (32mA-6.3A) and 30 minutes (8A-15A).

210% the fuse must open within 30 minutes maximum.

275% the fuse must open in a minimum of .05 seconds and a maximum of 2 seconds.

400% the fuse must open in a minimum of .01 seconds and a maximum of .3 seconds (125mA – 6.3A).

1000% the fuse must open within .02 seconds maximum.

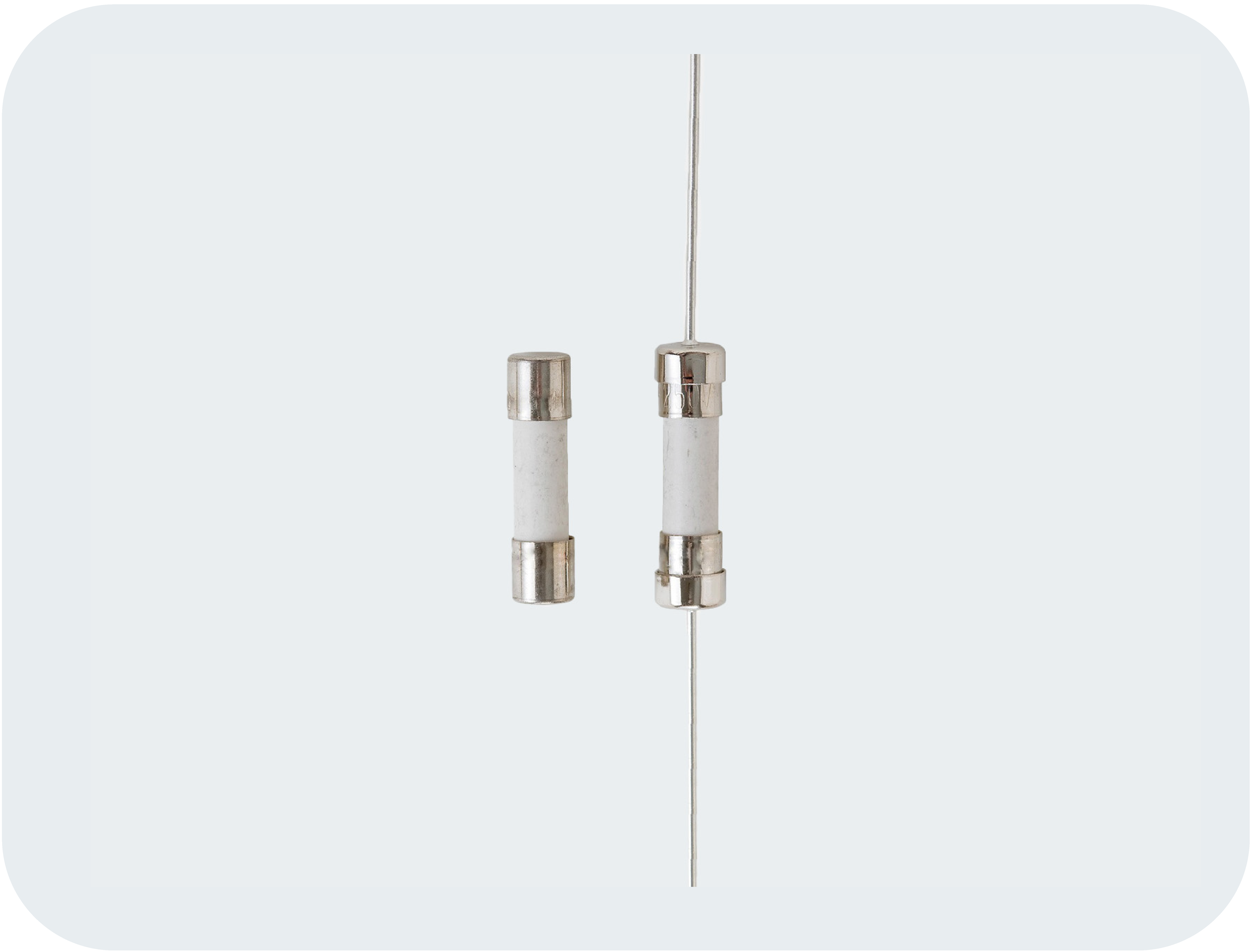

Ceramic vs. Glass Fuses

Tube fuses come in two main types: glass and ceramic. OptiFuse’s FSC Series represents the glass tube fuse line, while the FCC Series is their ceramic tube fuse family. The physical properties of the ceramic material make the ceramic fuses stronger than their glass counterparts. Ceramic fuses incorporate sand filling to improve their performance during short circuit failures.

The sand serves to quench the arcing, allowing the fuse to have a higher interrupting capacity. This means they can interrupt higher levels of fault currents without sustaining damage.

When choosing a fuse, glass is a good option for applications where the probability of a high current episode isn’t likely to occur (compare the Interrupt Rating to the potential current the fuse may be subjected to). They also allow for visual checks of a damaged filament. Ceramic has a higher breaking capacity offering a greater level of thermal and arc protection better suited for applications where high current episodes may occur.

In the case of a component shortage, you can usually substitute a ceramic fuse in place of a glass fuse, but you should not substitute a glass fuse for a ceramic fuse. Using a glass cartridge fuse as a substitute could result in the fuse envelope rupturing during a fault.

Axial-leaded Fuses

All of the OptiFuse electronic glass and ceramic fuses come with the option of adding an optional axial lead to the ends of the fuse that allow the fuse to be directly soldered into the PCB. A “-P” signifies an axial-lead designation to any standard fuse part number (ex. FSA-P-1A).

Axial leaded fuses are typically cost-effective and easy to install. However, choosing this method limits the future replacement of the fuse.

In contrast, the cartridge version of these fuses is designed to be mounted in a fuse block, clip, or holder, which can be either in-line or panel mounted, allowing for easier replacement and maintenance. To learn more about selecting the right fuse holder for your application, see our guide on how to choose a panel mounted fuse holder.

Samuel Kenny, Product Manager at OptiFuse, leads the development of advanced circuit protection products for automotive, marine, and industrial sectors. He designs custom solutions and shares expert fuse selection tips on the OptiFuse Blog.